Variety of LED Dimming Solutions

Tunable White Track Lights

Dynamic Lighting Solutions

Dynamic Lighting Solutions

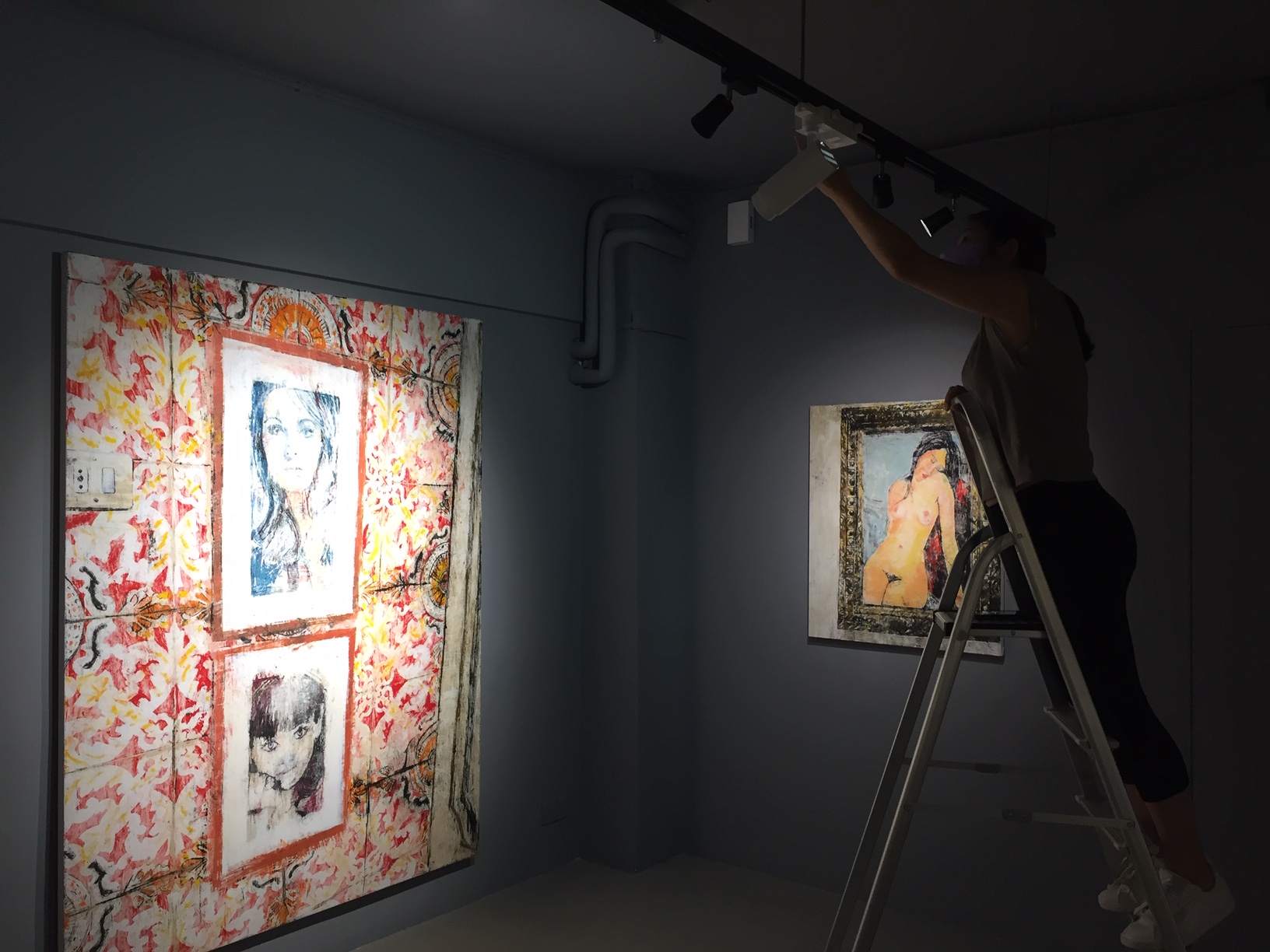

Art gallery, museum lighting, luxury display

Tunable White Track Lights

Art Galleries, Adjust Brightness and Color Temperature, Can Operate on 2 / 4-wire Rails

Variery of LED Dimming Solutions

AC / DC Modules, Aluminum Alloy Faceplate Wall Dimmers, Dimming Controllers